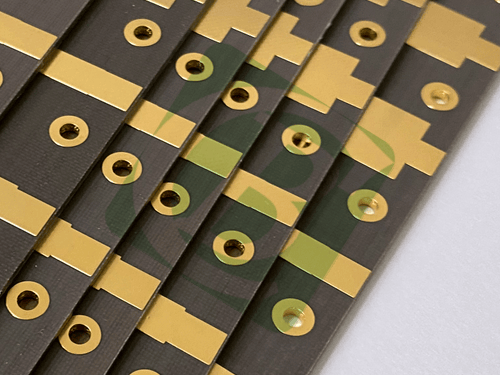

TLY-3 2-Layer 20mil Silver-Gold Plate PCB for Millimeter Wave Applications

1.Introduction

TLY-3 laminates are manufactured with very lightweight woven fiberglass and are much more dimensionally stable than chopped fiber reinforced PTFE composites. The woven matrix in the TLY-3 material yields a more mechanically stable laminate that is suitable for high volume manufacturing. The low dissipation factor enables successful deployment for automotive radar applications designed at 77 GHz as well as other antennas in millimeter wave frequencies.

Comparative OEM testing at 77 GHz of lightly reinforced TLY-3 vs. its closest chopped fiber reinforced competitor has shown "drop in"/equivalent insertion losses/dielectric properties. The primary benefit is much higher manufacturing yields. The dielectric constant range is 2.17 to 2.40. For most thicknesses, the dielectric constant can be specified anywhere within this range with a tolerance of +/-0.02. In the low dielectric constant range, the dissipation factor is approximately 0.0009 at 10 GHz. Typical applications include satellite communications, automotive radar, filters, couplers, avionics and phased array antennas.

2.Key Features

Ultra-Low Dielectric Constant: 2.33 ±0.02 at 10GHz

Exceptional Signal Integrity: Dissipation Factor of 0.0012 at 10GHz

Thermal Management: Thermal Conductivity of 0.22 W/mk (Unclad)

Dimensional Stability: x CTE 26 ppm/°C, y CTE 15 ppm/°C, z CTE 217 ppm/°C

Strong Bonding: Peel Strength 0.5oz 11 lbs/in, 1oz 17 lbs/in

Environmental Resistance: Low Moisture Absorption of 0.02%

Safety Certified: Flammability Rating of V-0

Space Qualified: Outgassing TML 0.01%, CVCM 0.01%, WVR 0.01%

3.Benefits

Manufacturing Excellence: Dimensionally Stable for high volume production

Superior RF Performance: Lowest Df for millimeter wave applications

Mechanical Reliability: High Peel Strength

Environmental Durability: Low Moisture Absorption

Consistent Performance: Uniform, Consistent Dk

Advanced Processing: Laser Ablatable for precision manufacturing

4.PCB Construction Details

| Parameter | Specification |

|---|---|

| Base Material | TLY-3 |

| Layer Count | 2-layer |

| Board Dimensions | 125mm × 47mm = 1PC, ±0.15mm |

| Minimum Trace/Space | 4/6 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias | No |

| Finished Board Thickness | 0.6mm |

| Finished Cu Weight | 1oz (1.4 mils) |

| Via Plating Thickness | 20 μm |

| Surface Finish | Silver plate / gold plate (Gold over silver) |

| Top Silkscreen | No |

| Bottom Silkscreen | No |

| Top Solder Mask | No |

| Bottom Solder Mask | No |

| Electrical Test | 100% tested prior to shipment |

5.PCB Stackup (2-Layer Rigid Structure)

Copper Layer 1 - 35μm (1oz)

TLY-3 Core - 20mil (0.508mm)

Copper Layer 2 - 35μm (1oz)

6.PCB Statistics:

Components: 25

Total Pads: 86

Thru Hole Pads: 64

Top SMT Pads: 22

Bottom SMT Pads: 0

Vias: 31

Nets: 2

7.Typical Applications

Automotive Radar (77GHz)

Satellite/Cellular Communications

Power Amplifiers

LNBs, LNAs, LNCs

Aerospace Systems

Ka, E and W band Applications

8.Quality Assurance

Artwork Format: Gerber RS-274-X

Accepted Standard: IPC-Class-2

Availability: Worldwide